Drastically Reduce Essential and Non-Essential Locomotive Idle Time With the Award Winning Electrolyte Lithium-Ion Based Idle Reduction System from ACS Railroad Solutions

- Reduce Fuel Consumption by $87K per year/per locomotive

- Reduce GHG emissions by ~ 2000 lbs. per day/per locomotive

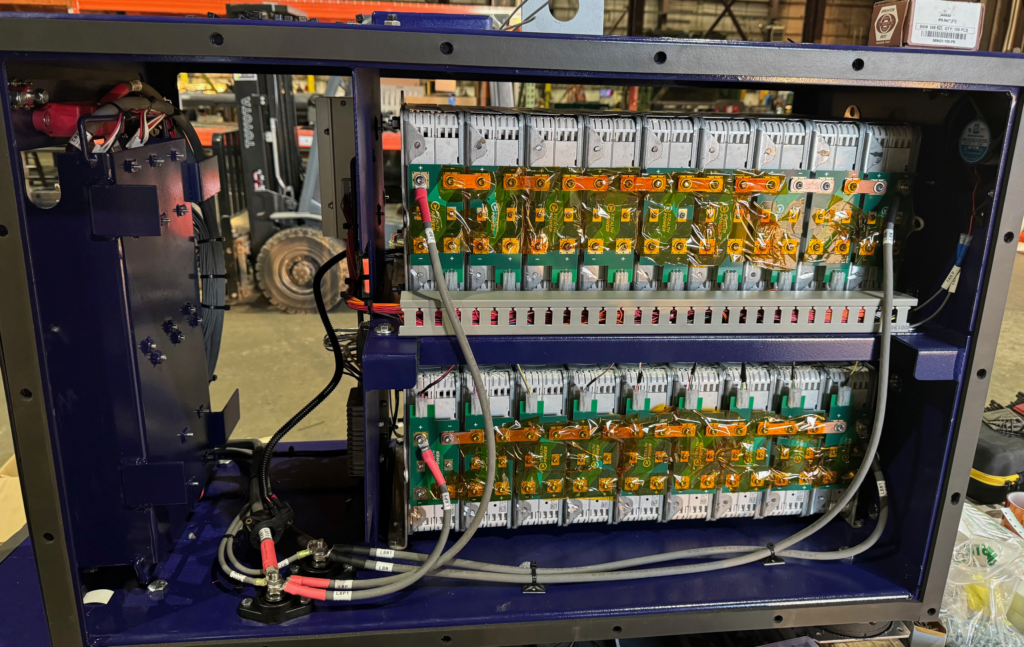

The Next Generation in Idle Reduction Technology

The ACS-RS Electrolyte Systems performs all the functions of a typical Automated Engine Start Stop (AESS) system but also leverages a 33 kWh Lithium-Ion based energy module to keep locomotive systems operational when the engine is shutdown

Go Above and Beyond a Legacy AESS System

- HVAC System remains fully operational, eliminating motivation for the crew to manually override the system

- Lighting remains active, video footage and predictive maintenance/locomotive analytic data continue to be captured

- System powers, monitors and controls the included make-up compressor minimizing the potential for restarts due to a drop in air brake pressure

- Energy Module maintains charge of Lead-Acid batteries and can be automatically activated if necessary to assist when the engine does need to restart

Conserve Fuel and Reduce GHG Emissions Caused by Unnecessary Idling